The Benefits of Using a Preventive Maintenance Spreadsheet

Learn how a preventive maintenance spreadsheet can streamline your maintenance operations, improve efficiency, and save costs in the long run.

Preventive maintenance is an essential aspect of maintaining equipment and machinery in top condition. It is the practice of regularly inspecting, cleaning, and servicing machines to prevent breakdowns and prolong their lifespan. A preventive maintenance spreadsheet is a powerful tool that helps you track and manage your maintenance operations efficiently. In this article, we’ll explore the benefits of using a preventive maintenance spreadsheet and how it can help you save time, money, and resources.

Streamline Maintenance Operations

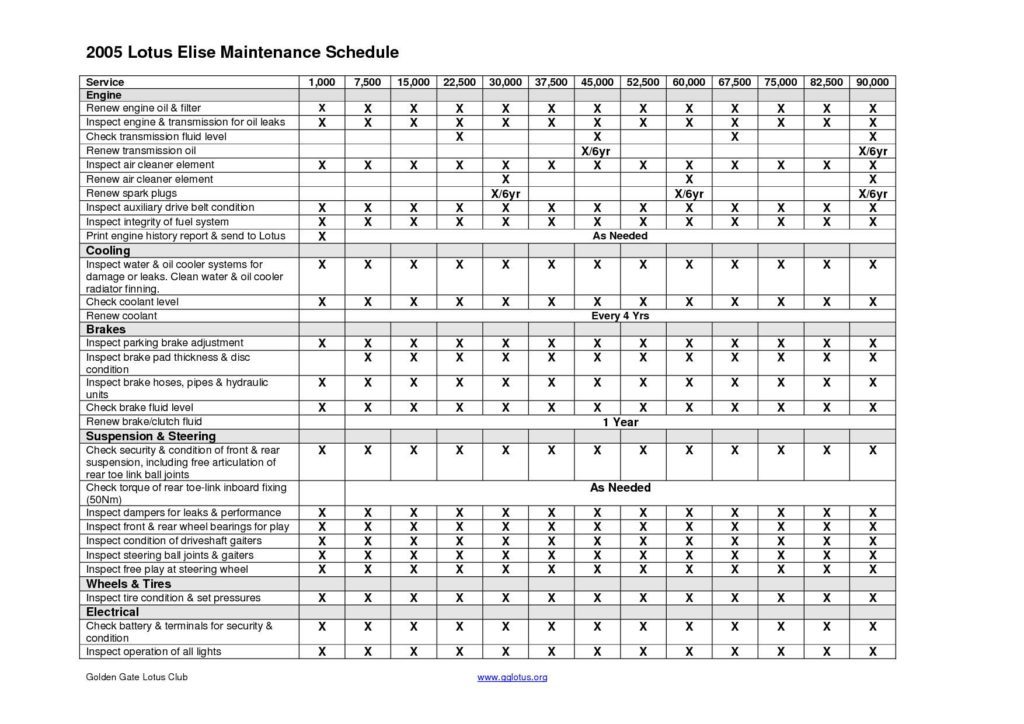

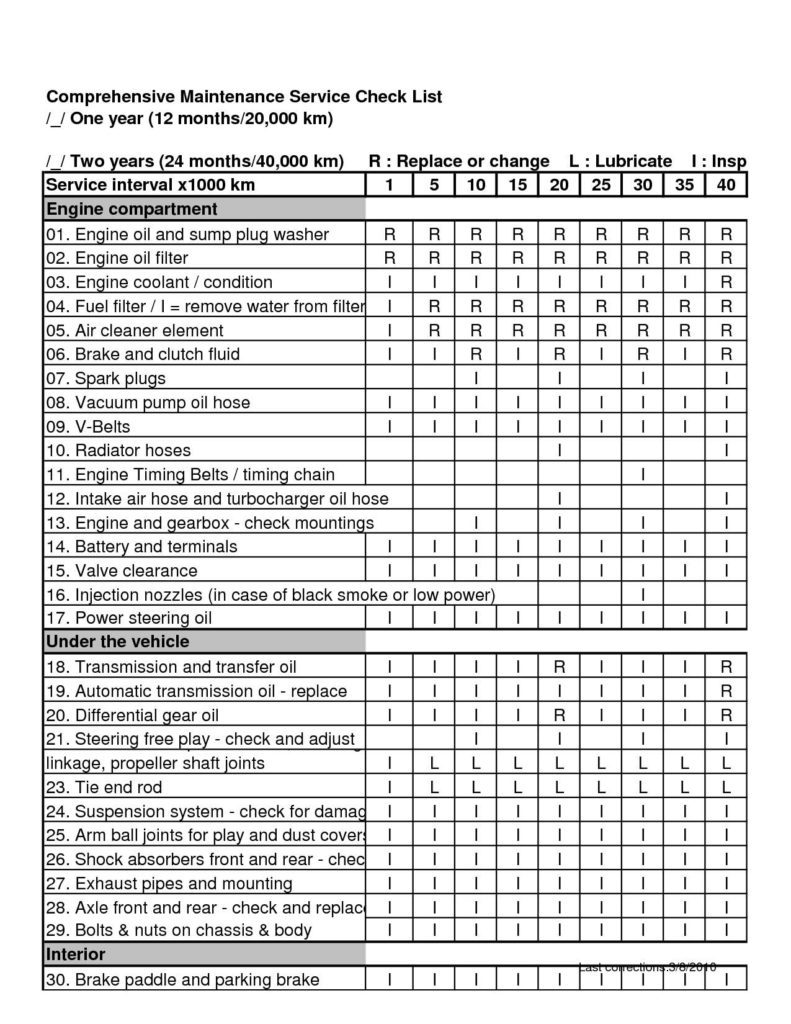

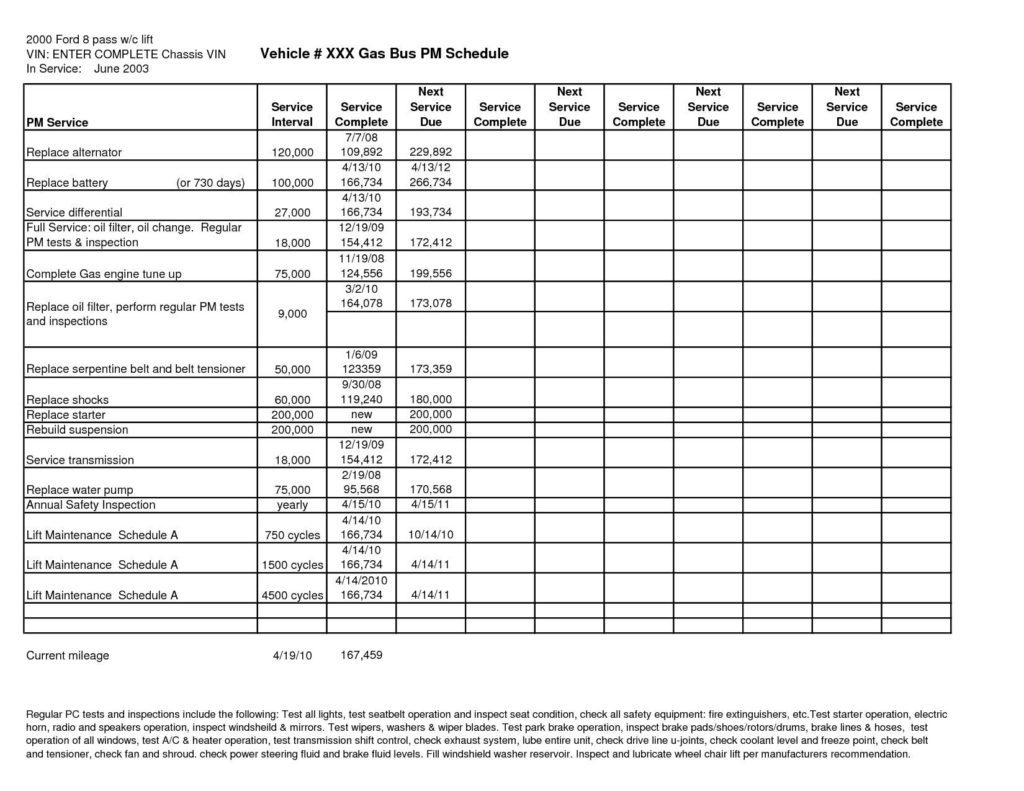

One of the main benefits of using a preventive maintenance spreadsheet is that it streamlines your maintenance operations. Instead of manually tracking and scheduling maintenance tasks, you can use a spreadsheet to automate the process. You can set up reminders for upcoming tasks, track the status of each task, and monitor equipment performance over time. This helps you stay on top of maintenance requirements and reduces the risk of equipment failure.

Improve Efficiency

By using a preventive maintenance spreadsheet, you can improve your maintenance efficiency. You can easily access all the information you need to schedule maintenance tasks, assign them to technicians, and track progress. This helps you avoid delays, reduce downtime, and minimize disruptions to your production schedule. You can also use the data collected in the spreadsheet to analyze equipment performance, identify trends, and make informed decisions about future maintenance needs.

Save Costs

Preventive maintenance is a cost-effective way of maintaining equipment and machinery. By preventing breakdowns and prolonging the lifespan of your assets, you can save on repair and replacement costs. A preventive maintenance spreadsheet helps you track the cost of maintenance activities, identify areas where costs can be reduced, and make data-driven decisions about your maintenance budget. By optimizing your maintenance operations, you can save costs in the long run.

Ensure Compliance

In many industries, compliance with regulatory requirements is essential. A preventive maintenance spreadsheet can help you ensure compliance by tracking maintenance activities and generating reports that demonstrate your compliance with regulations. This can help you avoid fines, penalties, and legal issues that can arise from non-compliance.

Enhance Safety

Regular maintenance is crucial for ensuring the safety of equipment and personnel. A preventive maintenance spreadsheet helps you schedule and track safety inspections, identify potential hazards, and take corrective actions to eliminate them. This can help you create a safer work environment and reduce the risk of accidents and injuries.

Increase Asset Lifespan

Proper maintenance is key to extending the lifespan of your assets. With a preventive maintenance spreadsheet, you can schedule and track routine maintenance tasks, such as lubrication, cleaning, and inspections, which can significantly prolong the lifespan of your equipment. By taking care of your assets, you can maximize their value and minimize replacement costs.

Reduce Equipment Downtime

Equipment downtime can be costly, both in terms of lost productivity and repair costs. A preventive maintenance spreadsheet helps you avoid equipment downtime by identifying potential issues before they become major problems. By scheduling regular maintenance, you can catch issues early and take corrective action to prevent equipment failure.

Enhance Equipment Performance

Regular maintenance is essential for maintaining optimal equipment performance. A preventive maintenance spreadsheet helps you track equipment performance metrics, such as run time, downtime, and efficiency. By analyzing this data, you can identify areas for improvement, optimize your equipment settings, and enhance overall performance.

Improve Documentation

Proper documentation is critical for effective maintenance management. A preventive maintenance spreadsheet provides a central location for storing and tracking maintenance data, which can help you keep accurate records of maintenance tasks, costs, and equipment performance. This documentation can be useful for audits, compliance, and reporting purposes.

Increase Accountability

By using a preventive maintenance spreadsheet, you can increase accountability for maintenance tasks. You can assign tasks to specific technicians, track their progress, and monitor completion rates. This can help you identify areas where improvements are needed and ensure that maintenance tasks are completed on time and to a high standard.

In summary, a preventive maintenance spreadsheet is a powerful tool that can help you optimize your maintenance operations, save costs, and improve equipment performance. It can help you schedule and track maintenance tasks, ensure compliance, enhance safety, increase asset lifespan, reduce equipment downtime, improve documentation, and increase accountability. By implementing a preventive maintenance spreadsheet, you can take your maintenance operations to the next level and achieve your business goals.