Maintenance Tracking Spreadsheet: A Must-Have Tool for Businesses

Keeping track of maintenance activities for equipment and machinery is essential for any business, especially those in manufacturing and industrial sectors. A failure to perform timely maintenance can result in costly repairs, equipment downtime, and even workplace accidents. Fortunately, businesses can use a maintenance tracking spreadsheet to stay on top of maintenance activities and ensure equipment is in good working condition. In this article, we’ll discuss what a maintenance tracking spreadsheet is, its benefits, and how to create one.

What is a Maintenance Tracking Spreadsheet?

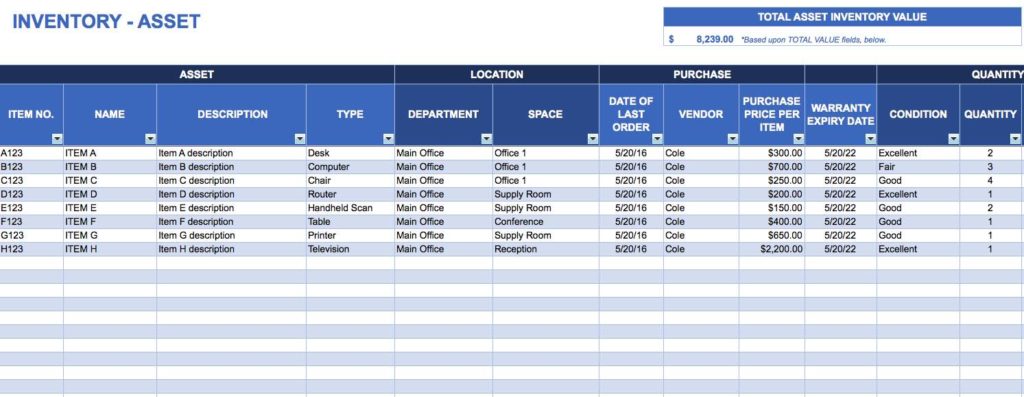

A maintenance tracking spreadsheet is a tool that allows businesses to record, track, and manage maintenance activities for their equipment and machinery. It typically includes details such as the equipment name, model number, serial number, maintenance schedule, and maintenance history. By using a maintenance tracking spreadsheet, businesses can ensure that maintenance activities are performed on time, identify any issues or trends, and plan for future maintenance.

Benefits of Using a Maintenance Tracking Spreadsheet

- Prevent Breakdowns: Regular maintenance can help prevent equipment breakdowns and ensure equipment is in good working condition. By using a maintenance tracking spreadsheet, businesses can schedule and track maintenance activities to ensure all equipment is properly maintained.

- Increase Safety: Equipment that is not properly maintained can pose a safety risk to employees. By using a maintenance tracking spreadsheet, businesses can ensure that all safety-related maintenance activities are performed on time and reduce the risk of workplace accidents.

- Prolong Equipment Lifespan: Proper maintenance can help prolong the lifespan of equipment and machinery. By using a maintenance tracking spreadsheet, businesses can ensure that equipment is properly maintained and in good working condition, thus extending its lifespan.

- Reduce Downtime: Equipment breakdowns can result in costly downtime for businesses. By using a maintenance tracking spreadsheet, businesses can schedule and perform maintenance activities to prevent breakdowns and reduce equipment downtime.

Creating a Maintenance Tracking Spreadsheet

Creating a maintenance tracking spreadsheet is relatively easy, and can be done using a program like Microsoft Excel or Google Sheets. Here are some tips for creating an effective maintenance tracking spreadsheet:

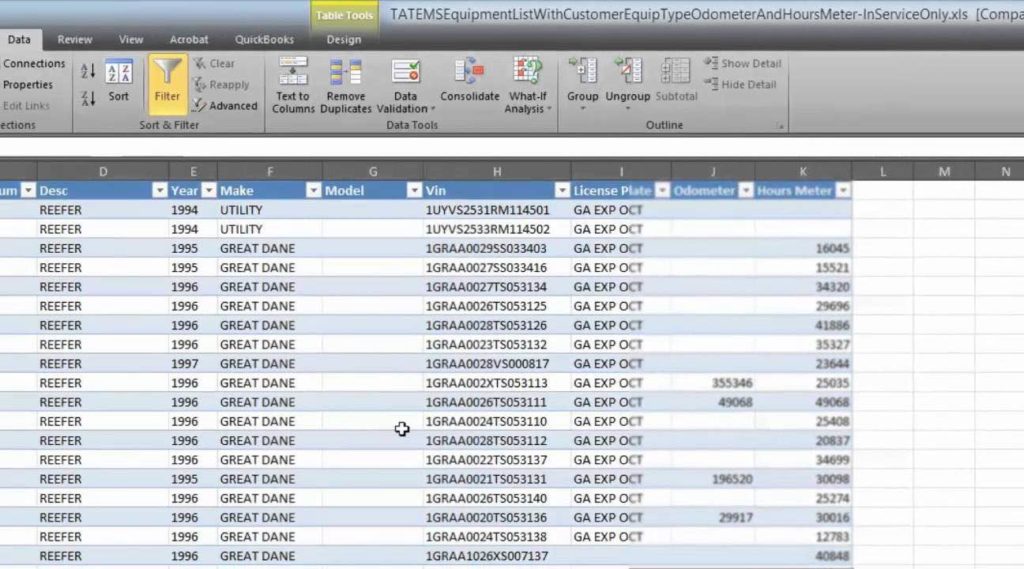

- List All Equipment: The first step to creating a maintenance tracking spreadsheet is to list all the equipment that needs maintenance. You can include details such as the equipment name, model number, serial number, and other relevant information.

- Schedule Maintenance: Once you have listed all the equipment, schedule maintenance activities for each item. You can include details such as the type of maintenance required, the date of the last maintenance, and the date of the next maintenance.

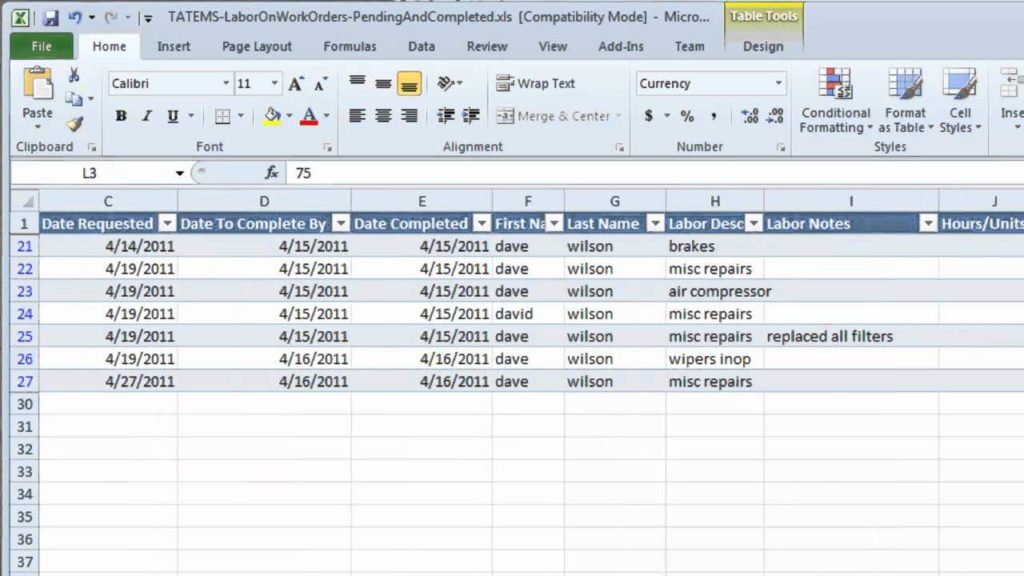

- Record Maintenance Activities: Record all maintenance activities performed on the equipment. You can include details such as the date, the person who performed the maintenance, and any notes or comments.

- Use Color Coding: Use color coding to highlight overdue maintenance activities, upcoming maintenance activities, and completed maintenance activities.

- Generate Reports: Use your maintenance tracking spreadsheet to generate reports on maintenance activities. These reports can be used to identify trends, analyze costs, and plan future maintenance activities.

An effective maintenance tracking system can help organizations save money, reduce downtime, and improve safety. One way to track maintenance is by using a maintenance tracking spreadsheet, which is a powerful tool for keeping track of equipment and ensuring it stays in good working condition.

What is a maintenance tracking spreadsheet?

A maintenance tracking spreadsheet is a tool that allows you to keep track of all the equipment and machinery in your organization, including its location, maintenance history, and current condition. It helps to ensure that your equipment is properly maintained and in good working order, reducing the risk of breakdowns, accidents, and unplanned downtime.

What are the benefits of using a maintenance tracking spreadsheet?

There are several benefits to using a maintenance tracking spreadsheet in your organization, including:

- Improved maintenance scheduling: With a maintenance tracking spreadsheet, you can easily schedule preventive maintenance for your equipment, ensuring that it stays in good working condition and minimizing the risk of breakdowns.

- Increased productivity: By keeping your equipment in good working order, you can avoid unplanned downtime and ensure that your operations run smoothly, increasing productivity and reducing costs.

- Better safety: Proper maintenance of equipment is essential for ensuring a safe working environment, and a maintenance tracking spreadsheet can help you keep track of safety inspections, repairs, and other maintenance tasks.

- Reduced maintenance costs: By keeping track of your equipment’s maintenance history and current condition, you can avoid costly repairs and replacements and instead focus on preventive maintenance, which is often less expensive.

How to use a maintenance tracking spreadsheet

To use a maintenance tracking spreadsheet effectively, you should follow these steps:

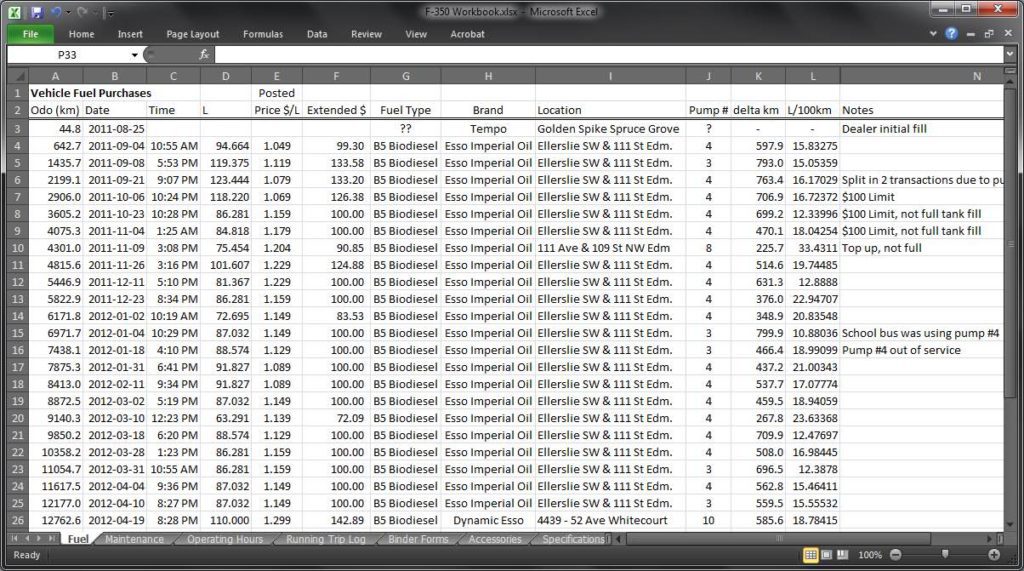

- Identify the equipment you want to track: This could include machinery, vehicles, or other equipment that is essential to your operations.

- Create a spreadsheet: Use a spreadsheet program such as Microsoft Excel to create a template for your maintenance tracking spreadsheet. You can use pre-built templates or create your own based on your organization’s needs.

- Enter equipment details: Enter details about each piece of equipment you want to track, including its name, location, maintenance history, and current condition.

- Schedule maintenance tasks: Use the spreadsheet to schedule maintenance tasks for each piece of equipment, including regular inspections, preventive maintenance, and repairs.

- Track maintenance history: As maintenance tasks are completed, update the spreadsheet to reflect the maintenance history for each piece of equipment.

- Analyze data: Use the data in your maintenance tracking spreadsheet to identify trends and make informed decisions about your maintenance program, such as which equipment needs more frequent maintenance or which tasks can be automated.

Conclusion

A maintenance tracking spreadsheet is a powerful tool for organizations looking to improve their maintenance program and reduce costs. By tracking equipment maintenance and scheduling preventive maintenance tasks, organizations can avoid breakdowns, increase productivity, and improve safety. With the right spreadsheet template and a commitment to regular maintenance, any organization can benefit from using a maintenance tracking spreadsheet.