In the realm of welding, precision and attention to detail are paramount for successful projects. Ensuring the quality and safety of welds is a critical aspect, and an effective Welding Inspection Report Template can significantly contribute to achieving this goal. At Pruneyard Inn, we understand the importance of meticulous inspection, and our Welding Inspection Report Template is designed to simplify the process while maintaining the highest standards.

Why a Welding Inspection Report Template?

- Systematic Documentation

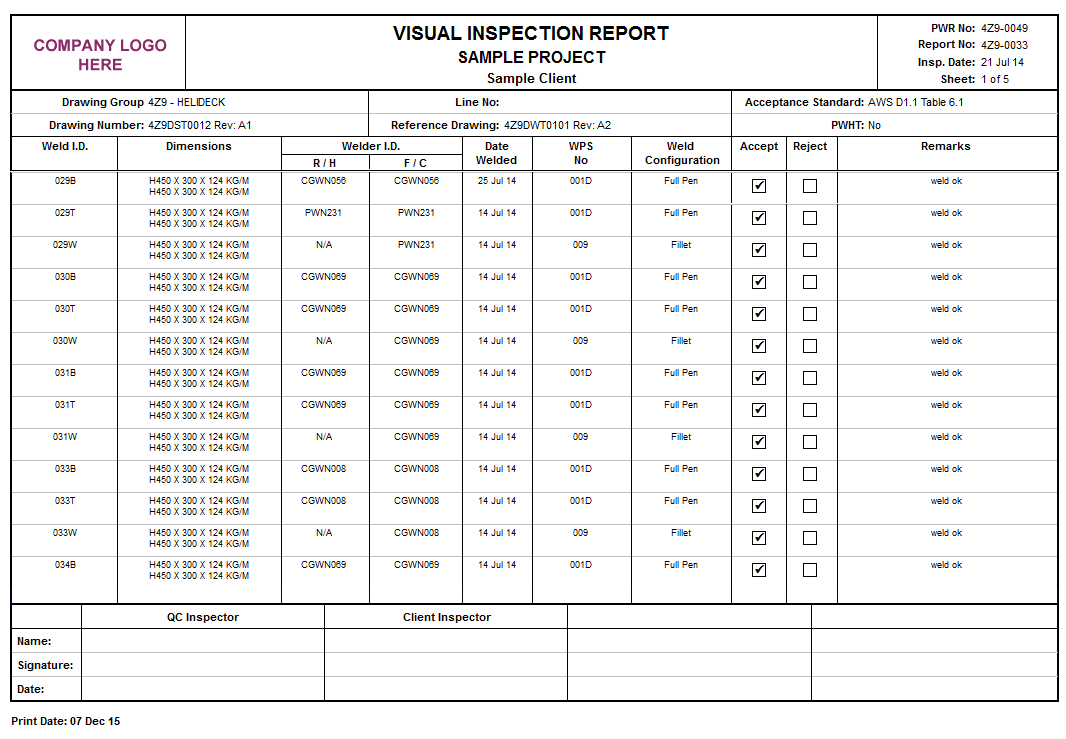

The Welding Inspection Report Template offered by Pruneyard Inn provides a systematic approach to documenting the inspection process. From initial assessments to final evaluations, every step is meticulously recorded, ensuring a comprehensive overview of the welding quality. - Customizable Fields

Every welding project is unique, and our template recognizes this diversity. With customizable fields, you can tailor the report to match the specific requirements of your project, allowing for flexibility and adaptability. - Time Efficiency

Time is of the essence in the welding industry. Our template is designed to optimize the inspection process, reducing the time spent on documentation without compromising the accuracy and thoroughness of the report.

Key Features of Pruneyard Inn’s Welding Inspection Report Template

- Project Details Section

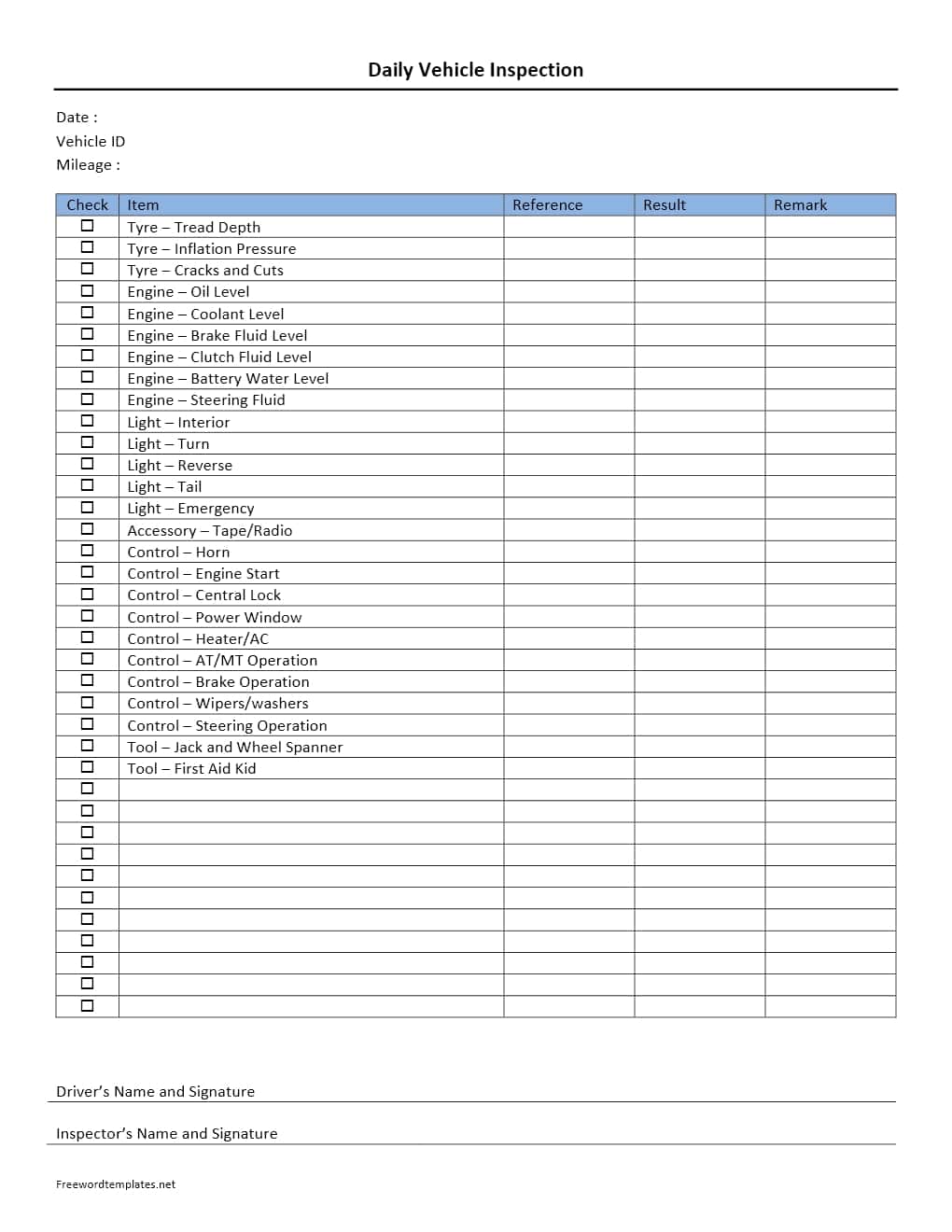

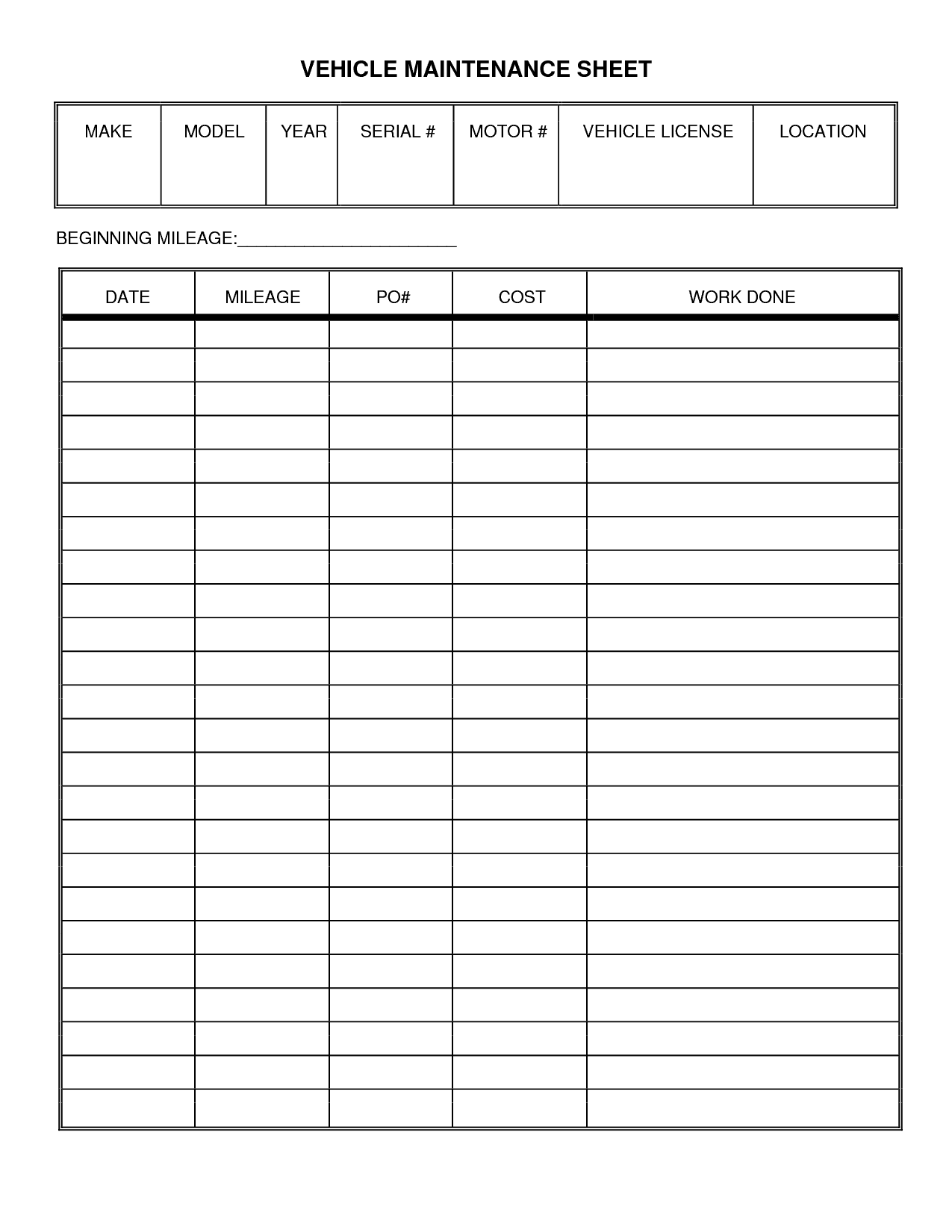

Begin with a detailed overview of the project, including project name, location, and key stakeholders. This section sets the stage for a clear understanding of the context surrounding the welding inspections. - Inspection Criteria Checklist

Our template includes a comprehensive checklist of common welding inspection criteria. From weld joint design to material selection, this checklist ensures that no critical aspect is overlooked during the inspection process. - Visual Documentation

A picture is worth a thousand words. The template allows for the inclusion of visual documentation, such as photographs or diagrams, to provide a visual representation of the inspected welds. - Defect Classification and Severity

Easily categorize defects based on their severity, allowing for a clear communication of issues that need immediate attention and those that can be addressed in subsequent stages of the project. - Inspector’s Notes and Recommendations

Encourage open communication between inspectors and project stakeholders by providing a dedicated section for notes and recommendations. This fosters collaboration and ensures that everyone is on the same page regarding the project’s welding quality.

How to Use the Welding Inspection Report Template

- Download the Template

Head to Pruneyard Inn’s website and download the Welding Inspection Report Template. It’s available in user-friendly formats like PDF and Excel, making it accessible for various users. - Customize as Needed

Tailor the template to your project’s specific requirements by filling in project details, modifying checklist items, and adjusting fields to match your unique needs. - Implement Efficient Inspections

Utilize the template during welding inspections to document every detail accurately. The organized structure ensures that no aspect of the inspection is overlooked. - Collaborate and Improve

Use the template as a collaborative tool, encouraging feedback and improvement suggestions. This iterative process ensures continuous enhancement of welding quality on your projects.

Ensuring Compliance and Safety

One of the paramount aspects of welding inspections is ensuring compliance with industry standards and regulations. Pruneyard Inn’s Welding Inspection Report Template aligns with various welding codes and standards, including AWS D1.1, ASME Section IX, and ISO 3834. This ensures that your welding projects adhere to the necessary guidelines, promoting not only quality but also safety.

User-Friendly Interface for Enhanced Accessibility

Navigating through the Welding Inspection Report Template is a breeze, thanks to its user-friendly interface. Whether you are a seasoned welding inspector or a project manager overseeing multiple facets of a construction project, the intuitive design allows for seamless interaction with the template. No need for extensive training—simply download, customize, and implement.

Adaptability to Various Welding Processes

Understanding that welding projects encompass a spectrum of processes, our template is versatile enough to accommodate different welding techniques. Whether you’re dealing with arc welding, gas welding, or resistance welding, the template can be easily adapted to suit your specific needs, making it a valuable tool across various industry sectors.

Quality Control Integration

Incorporating a stringent quality control process is essential for successful welding projects. Pruneyard Inn’s template facilitates efficient quality control integration by offering designated sections for welder qualifications, inspection dates, and non-destructive testing results. This holistic approach ensures that the welding inspection process is not only thorough but also compliant with the highest quality standards.

Continuous Improvement through Data Analysis

Beyond its immediate use in project documentation, the Welding Inspection Report Template serves as a valuable resource for data analysis. By consistently utilizing the template and analyzing the compiled reports, you gain insights into recurring issues, potential areas for improvement, and trends in welding quality. This data-driven approach empowers you to implement proactive measures, enhancing overall project efficiency.

Customer Testimonials

“Pruneyard Inn’s Welding Inspection Report Template has revolutionized the way we approach welding inspections. The customizable fields and detailed checklist have streamlined our documentation process, allowing us to focus more on the actual inspection. It’s a game-changer for anyone serious about welding quality.”

— John Mitchell, Project Manager, Steel Dynamics Inc.

“As a welding inspector, I appreciate the attention to detail in Pruneyard Inn’s template. It’s comprehensive yet easy to use, making my job more efficient. The ability to include visual documentation is a particularly valuable feature that sets it apart from other templates.”

— Sarah Rodriguez, Certified Welding Inspector

Conclusion: Elevate Your Welding Inspections with Pruneyard Inn

In conclusion, the Welding Inspection Report Template from PruneyardInn.com is not just a document; it’s a tool that empowers you to achieve excellence in welding quality. By combining meticulous documentation, user-friendly design, and adaptability to various welding processes, our template becomes an indispensable asset for professionals across the welding industry.

Download the Welding Inspection Report Template today and experience the difference firsthand. Streamline your inspections, ensure compliance, and elevate the quality of your welding projects with Pruneyard Inn’s commitment to precision, efficiency, and safety. It’s time to revolutionize your approach to welding inspections.