Improve your steel fabrication business efficiency with Steel Takeoff Spreadsheet. Read on to know how this innovative tool can help you estimate material requirements with ease.

As a steel fabricator, one of the most significant challenges you face is accurately estimating the quantity of steel required for a project. This process, known as takeoff, involves analyzing the project drawings and calculating the materials required to complete the project. The accuracy of your material estimation can impact project costs, deadlines, and client satisfaction.

Fortunately, with technological advancements, there is an innovative solution that can simplify this task – Steel Takeoff Spreadsheet. This tool can revolutionize the way you estimate materials for your steel fabrication projects. In this article, we will discuss how this innovative tool can help you enhance your steel fabrication business’s efficiency and accuracy.

What is a Steel Takeoff Spreadsheet?

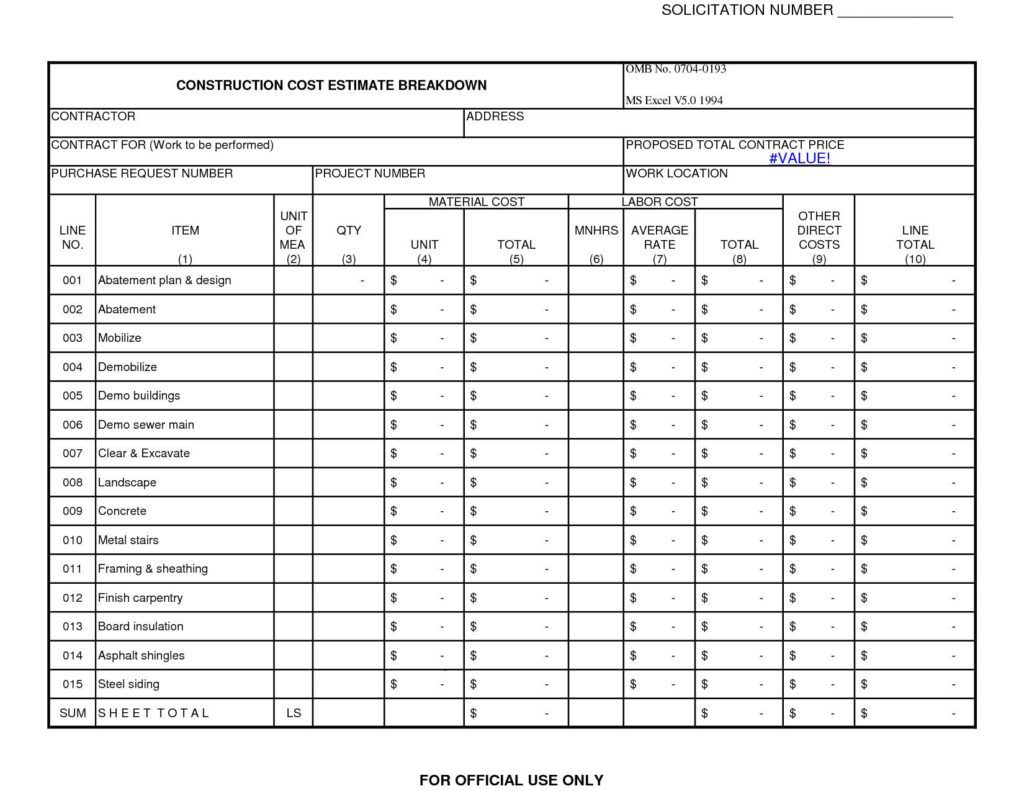

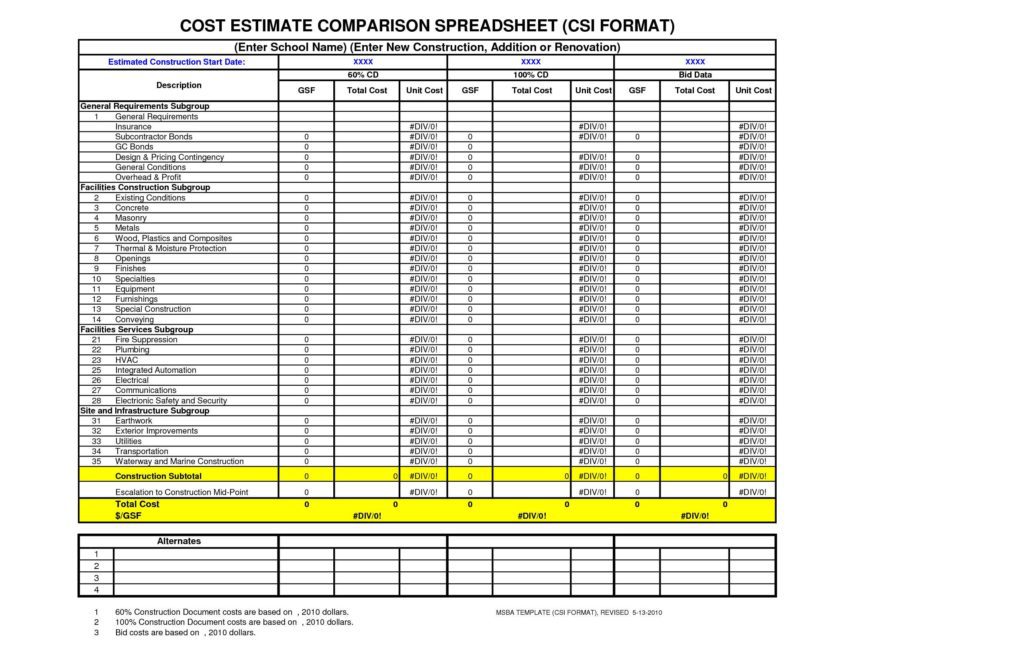

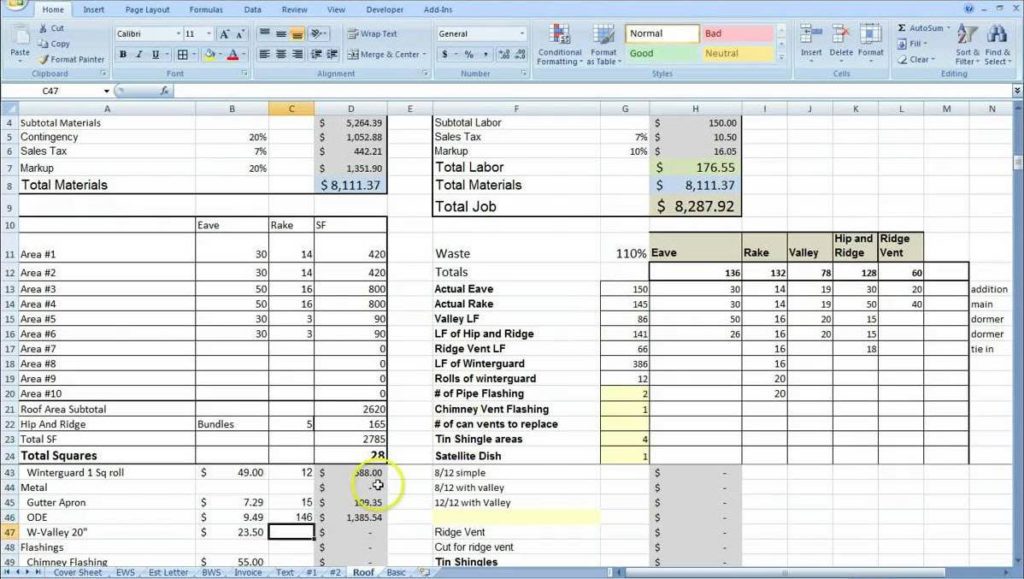

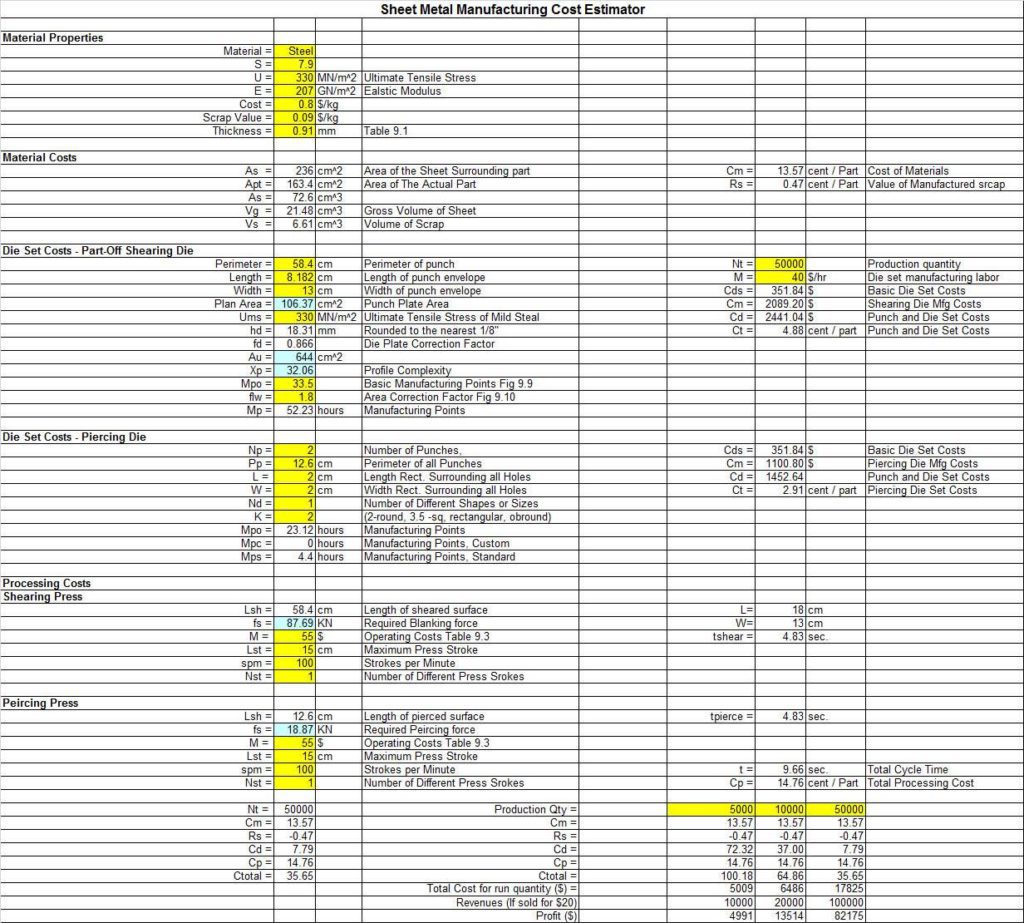

A Steel Takeoff Spreadsheet is a software tool that uses pre-programmed formulas to help steel fabricators estimate the materials required for a project. The spreadsheet is typically created in Microsoft Excel or Google Sheets, and the formulas are designed to calculate the quantity of steel required based on the project’s specifications.

How Can a Steel Takeoff Spreadsheet Help Your Business?

Using a Steel Takeoff Spreadsheet can provide numerous benefits to your steel fabrication business, including:

- Accurate Material Estimation

A Steel Takeoff Spreadsheet can help you accurately estimate the quantity of steel required for a project. This tool uses pre-programmed formulas that take into account project specifications, such as dimensions and weight, to calculate the materials required. This ensures that you have a precise estimate of the materials you need to complete the project. - Time-Saving

Manual takeoff is a time-consuming task that involves analyzing project drawings and making calculations. A Steel Takeoff Spreadsheet can simplify this process by automating the calculations, which can save you a significant amount of time. You can complete your material estimation in a fraction of the time it would take to do it manually. - Increased Efficiency

Using a Steel Takeoff Spreadsheet can enhance your business’s efficiency by streamlining the material estimation process. You can easily update project specifications and make changes to the spreadsheet, which can reduce errors and improve your workflow. - Improved Accuracy

Accurate material estimation is crucial to the success of a project. Using a Steel Takeoff Spreadsheet can reduce the likelihood of errors, ensuring that you have an accurate estimate of the materials required. This can help you stay within budget and meet project deadlines. - Competitive Advantage

Using a Steel Takeoff Spreadsheet can provide you with a competitive advantage in the steel fabrication industry. This innovative tool can help you complete projects more efficiently and accurately, which can improve client satisfaction and increase your business’s profitability.

How to Choose the Right Steel Takeoff Spreadsheet?

Choosing the right Steel Takeoff Spreadsheet can be challenging, as there are numerous options available in the market. Here are some factors to consider when selecting the right tool for your business:

- Functionality

Choose a tool that offers the functionalities you need to estimate materials accurately. Look for a tool that includes pre-programmed formulas for various types of steel materials and project specifications. - Compatibility

Ensure that the tool you choose is compatible with the software you use for project management. If you use Microsoft Excel or Google Sheets, choose a tool that integrates with these programs. - Ease of Use

The tool you choose should be easy to use and navigate. Look for a tool with an intuitive interface that allows you to input project specifications and generate accurate material estimates quickly. - Cost

The cost of the tool is an essential factor to consider. Look for a tool that fits within your budget and offers the functionalities you need. - Customer Support

Ensure that the tool you choose offers excellent customer support. Look for a tool with a dedicated support team that can help you troubleshoot any issues you encounter while using the tool.

Conclusion

In conclusion, selecting the right Steel Takeoff Spreadsheet is crucial to enhancing your steel fabrication business’s efficiency and accuracy. By considering the factors mentioned above, you can select a tool that meets your business’s needs and budget. With the right tool, you can streamline your material estimation process, improve your workflow, and boost your business’s profitability.

Final Thoughts

In today’s competitive steel fabrication industry, accurately estimating materials is crucial to the success of your projects. Using a Steel Takeoff Spreadsheet can simplify this task and provide numerous benefits to your business. By selecting the right tool, you can streamline your material estimation process, reduce errors, and improve your workflow. Start using a Steel Takeoff Spreadsheet today and take your steel fabrication business to the next level.